01

Expertise

The coffee roasting process is an ancient, super-heated spectacle. A coffee roaster is effectively a large tumble dryer, although rather than heating to 40’c, it runs at around 180 – 200’c. The beans are dropped into the roaster at room temperature and heated on a controlled path called a profile, which has been predetermined through tasting and fine tuning, using the adjustable heat, drum speed and air drawn through by a powerful fan. All of these are hand controlled every inch of the coffee roasting process by Rachael our master roaster and the roastery team.

02

Sample roasting

First, we seek out small samples of new coffees from farms around the globe which we roast on our sample roaster. We work to our standard profile which highlights the potential and characteristics a coffee has. It is at this point we can grade a coffee and check for defects and decide if it makes the Voyager grade!

03

Cupping

Eight to Twelve hours after sample roasting we cup our coffees for quality and flavour. To be more objective in our judgement, we score coffees using the SCA (Specialty Coffee Association) protocol where we score coffee out of ten for its aroma, acidity, body, sweetness and finish, which gives us an overall cup score. Over a final score of 80 and the coffee is deemed a speciality coffee.

04

Green Bean Storage

Our coffee deliveries arrive in 60-70kg hessian sacks, many with an extra layer Grain Pro bag inside to keep the beans extra fresh. Each delivery of coffee gets checked for quality and moisture tested for an ideal percentage of around 11%, then stored in a cool dark place atop a pallet.

05

Roast Profile

Each coffee has its own personal profile that we develop through tasting and speciality to bring out the best possible flavour from our coffees. The profile incorporates our drop in temperatures, control adjustments, bean and exhaust temperatures, rates of temperature rise, the all-important first crack and development times. By following this each time, every roast can be consistent.

06

Genio Controls

Our Genio roasters precision control system allows full control over gas pressure, air flow pressure and drum speed, so every one of our delicious coffees are truly hand roasted.

07

Colour

We use a high tech colour meter for testing the colour of each roasted batch. This ensures our roasts are consistent each and every time.

08

Batch Notes

During and after roasting we document everything from temperature rise and fall, rate of rise, colour changes, point of first-crack and batch cupping notes. By documenting everything this way, we can identify any seasonal and environmental changes which help us to improve and keep our coffee tasting great throughout the year.

09

More Cupping

Every week we cup our roasts for quality control prior to blending or packing. It’s important to taste, taste, and taste some more, to maintain our coffee profiles and to watch out for any seasonal differences which may occur. This way we can be on top of our coffee game.

10

Package Weighing and Filling

After our coffees have been roasted, tasted and approved, we move them to the packing area. Here we carefully weigh each pack of coffee into bags fitted with one-way valves to allow the coffee to “de-gas” without allowing oxygen in, which will stale the coffee. They are then boxed ready for our customers.

11

Delivery

As much as possible and to ensure our customers receive the freshest coffee, our friendly coffee champions deliver to your door on a weekly basis in our Voyager vans. This also means we are always on the ground with our customers should they need any tips or advice.

12

Drinking and Enjoyment

Finally, the coffee process reaches its finale when a Voyager trained barista serves the most delicious coffee for their customers to drink and enjoy!

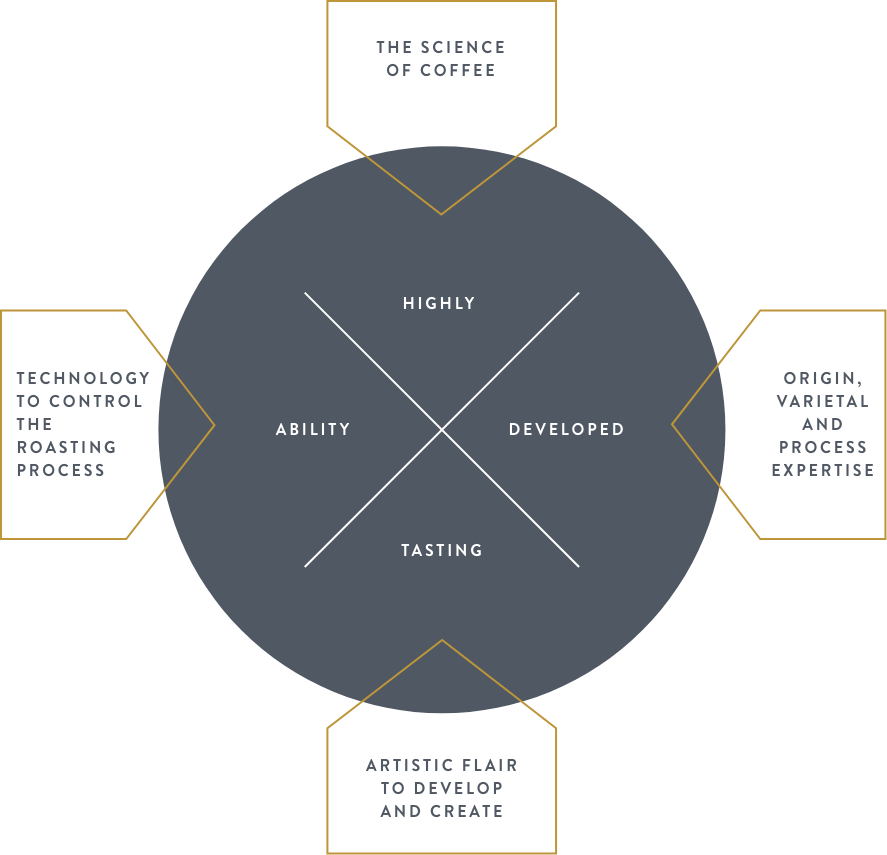

Roasting well combines: